The Significance of Precision Machined Components for Hardware Stores

Introduction

In the competitive world of hardware stores, the quality and reliability of the products offered play a vital role in attracting and retaining customers. One essential aspect that distinguishes a hardware store from its competitors is the availability of top-notch precision machined components.

Titan Bolts, the leading supplier of precision machined components, ensures that hardware stores receive high-quality products that cater to diverse industry needs. In this article, we delve into the significance of precision machined components and how they can help hardware stores thrive in the market.

Understanding Precision Machined Components

Precision machined components are intricately designed parts, created using advanced manufacturing techniques and high-precision machinery. These components are crucial in various industries, including automotive, aerospace, electronics, and more.

Hardware stores that offer precision machined components provide customers with access to reliable and durable solutions for their projects. Whether it's screws, bolts, washers, or other components, the precision manufacturing process ensures that each part meets exact specifications, resulting in accurate and efficient performance.

The Importance of High-Quality Precision Machined Components

1. Reliability:

High-quality precision machined components are known for their exceptional reliability. When customers purchase components from a reputable hardware store like Titan Bolts, they can trust that each part will perform optimally, minimizing the risk of product failure or breakdowns.

2. Enhanced Performance:

Precision machined components are engineered for optimal performance. By using these components, hardware stores can assure their customers that the products they purchase will deliver superior efficiency, accuracy, and durability.

3. Safety and Quality Standards:

Hardware stores need to prioritize safety and quality in the products they offer. Precision machined components adhere to strict industry standards and regulations, ensuring that customers can rely on their quality and safety.

4. Versatility and Compatibility:

The precision manufacturing process results in components that are highly versatile and compatible with a wide range of applications. This allows customers to find the perfect precision machined component for their specific needs, regardless of the industry they operate in.

Industries that Benefit from Precision Machined Components

A multitude of industries thrive on the use of precision machined components to enhance their operations:

- Automotive: Precision machined components are vital in automotive manufacturing, contributing to the efficiency, performance, and safety of vehicles.

- Aerospace: The aerospace industry heavily relies on precision components to ensure the reliability and safety of aircraft and satellite systems.

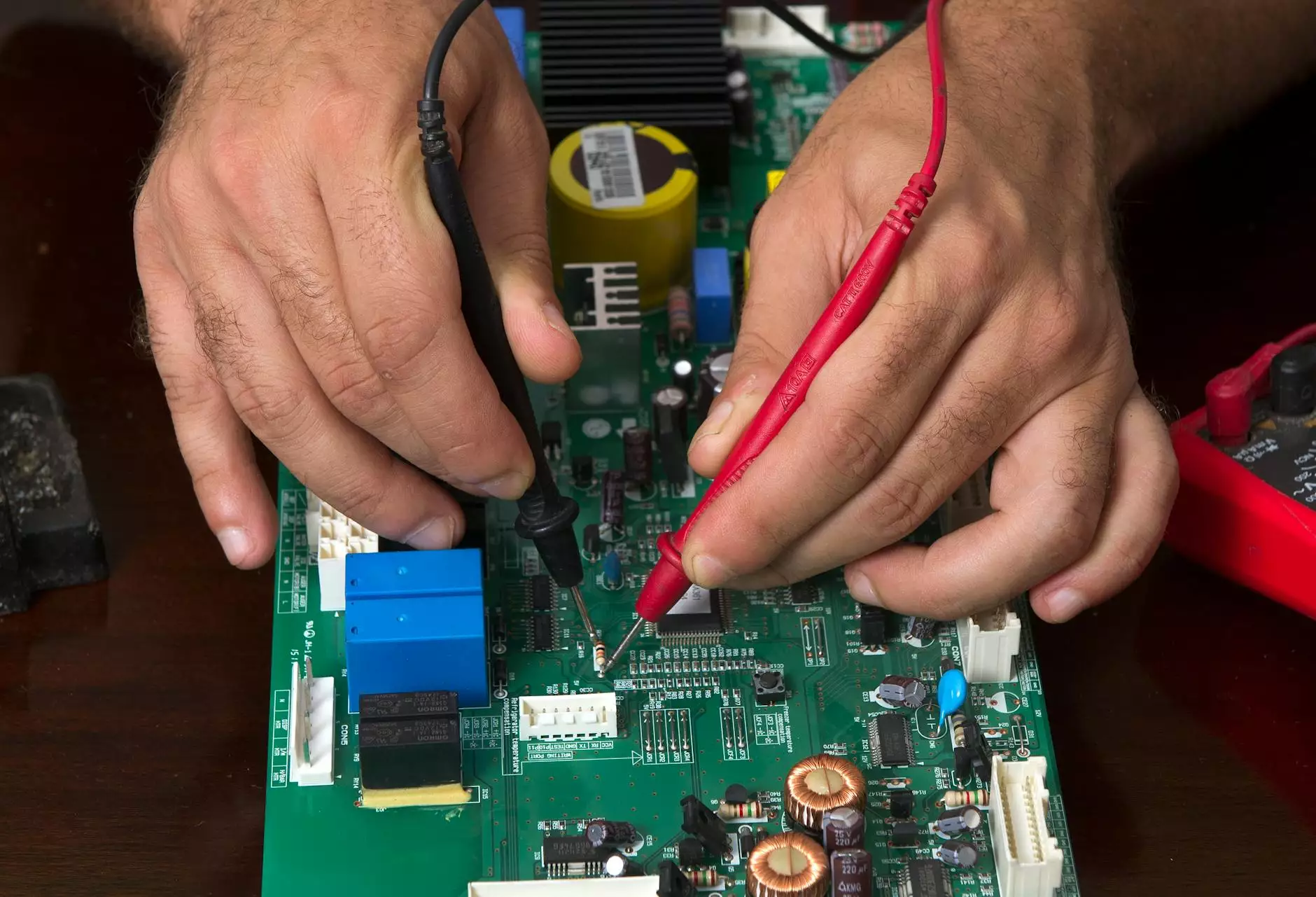

- Electronics: In the electronics sector, precision machined components support the production of circuit boards, connectors, and other essential electronic devices.

- Medical: The medical field has stringent quality standards, making precision machined components indispensable for surgical tools, implants, and medical devices.

- Construction: Precision components help in construction projects where accuracy and strength are critical, such as structural elements and load-bearing applications.

Choosing the Right Precision Machined Components Supplier

When it comes to sourcing precision machined components for a hardware store, it is crucial to partner with a reliable and trusted supplier like Titan Bolts. Here are some factors to consider:

- Quality Control: Ensure that the supplier has robust quality control processes in place to deliver consistently excellent components.

- Manufacturing Capabilities: Look for a supplier with advanced manufacturing capabilities, including CNC machining and state-of-the-art equipment.

- Industry Expertise: Partnering with a supplier who possesses extensive knowledge and experience in providing components for various industries is advantageous.

- Customization Options: The ability to offer customized solutions allows you to cater to specific customer requirements.

- Timely Delivery: Prompt delivery is crucial to meet customer demands and maintain a competitive edge in the market.

The Future of Precision Machined Components

The demand for precision machined components continues to grow across industries as technology advances and customer expectations rise. As a hardware store, offering a comprehensive range of precision machined components positions your business as a go-to source for industry-specific needs.

By partnering with Titan Bolts, you gain a competitive edge in the market, ensuring that your customers receive top-quality precision machined components backed by excellent service and expertise.

Conclusion

Investing in precision machined components is a wise choice for hardware stores looking to stand out in a crowded market. The value they offer in terms of reliability, enhanced performance, and adherence to industry standards is unparalleled. Titan Bolts, with its wide selection of precision machined components, is an ideal partner to meet the diverse needs of hardware stores catering to various industries.

Choose Titan Bolts for precision machined components – a supplier that prioritizes quality, customer satisfaction, and long-term success. Elevate your hardware store's reputation and foster trust among customers who seek the best precision components available.