Unlocking Business Success in Metal Fabrication: The Power of Partnering with Leading CNC Machine Suppliers

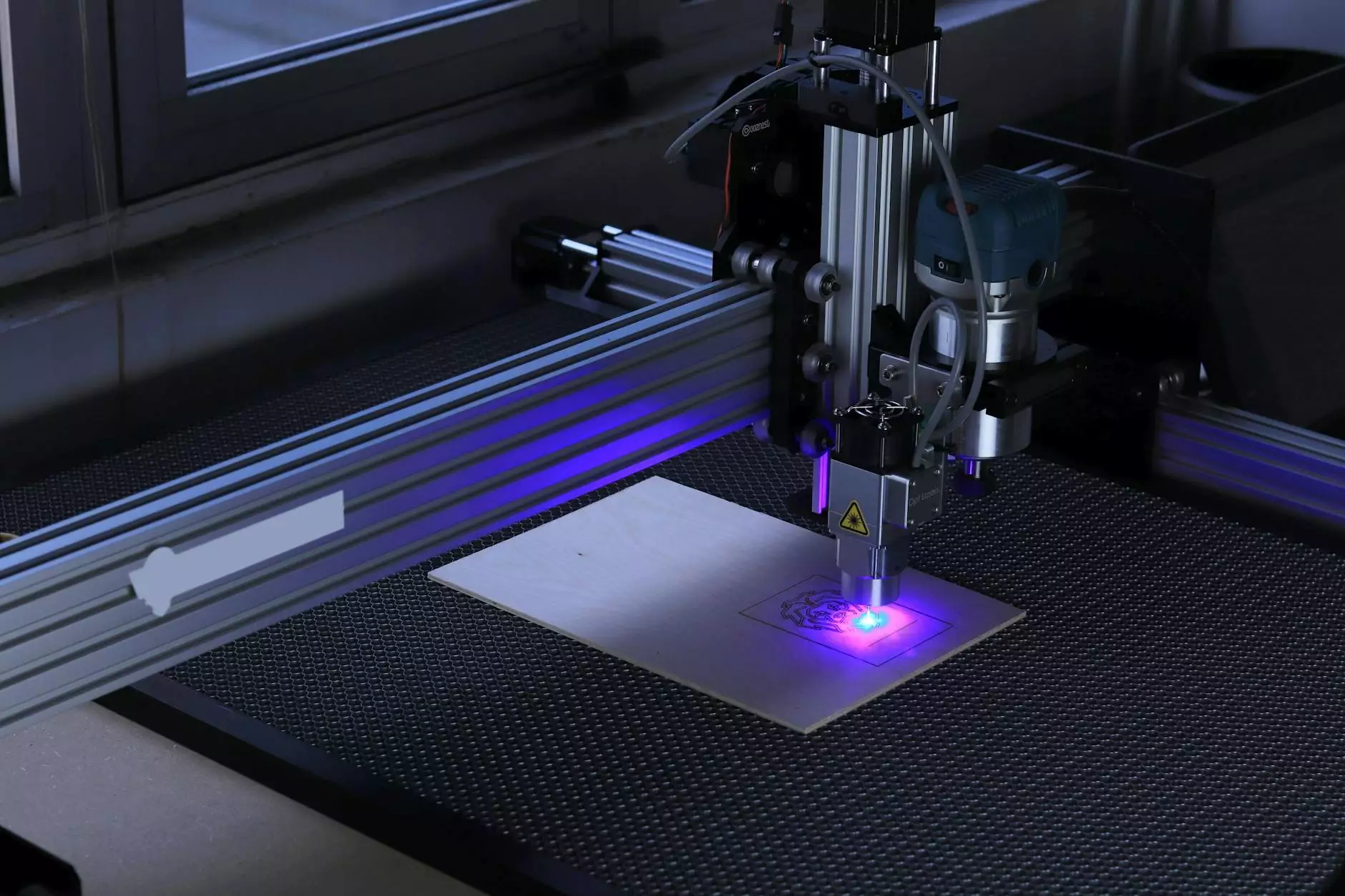

In the rapidly evolving world of manufacturing, especially within metal fabricators, staying ahead requires more than just skilled labor and innovative ideas. It demands cutting-edge machinery, strategic partnerships, and an unwavering focus on quality and efficiency. At the heart of this technological advancement lie cnc machine suppliers—the pioneers providing state-of-the-art equipment that propels your business into new realms of productivity and precision.

Why CNC Machine Suppliers Are the Cornerstone of Modern Metal Fabrication

Over the past few decades, Computer Numerical Control (CNC) technology has revolutionized manufacturing processes. The integration of sophisticated CNC machines has enabled metal fabricators to achieve unprecedented levels of accuracy, repeatability, and automation. By collaborating with reliable cnc machine suppliers, businesses gain access to advanced hardware that streamlines production workflows and elevates product quality.

The Critical Role of CNC Machines in Metal Fabrication

- Precision and Consistency: CNC machines produce consistently high-quality components, minimizing errors and waste.

- Automation and Efficiency: Reduces manual labor, speeds up production cycles, and enables 24/7 manufacturing capabilities.

- Complex Design Capability: Handles intricate and complex designs that are difficult or impossible with manual tools.

- Cost-Effectiveness: Long-term savings through reduced material waste, lower labor costs, and faster turnaround times.

How to Choose the Right CNC Machine Suppliers for Your Metal Fabrication Business

Partnering with trustworthy cnc machine suppliers is crucial for maintaining competitive advantage. Here are key considerations to ensure you select the best supplier for your needs:

1. Examine the Range of Equipment Offered

Opt for suppliers providing a comprehensive portfolio of CNC machines—including CNC mills, lathes, routers, and multi-axis systems. An extensive product range allows customization aligned with your specific manufacturing demands.

2. Focus on Quality and Reliability

Prioritize suppliers known for manufacturing durable, high-precision machinery. Look for industry certifications, customer reviews, and after-sales service support to gauge reliability.

3. Technical Support and Training Services

Ensure your supplier offers robust technical assistance, training programs, and maintenance services. Empowering your workforce with knowledge helps maximize equipment uptime and efficiency.

4. Cost and Financing Options

While quality is paramount, affordability and flexible leasing or financing options can ease initial investment burdens and facilitate upgrading over time.

5. Innovation and Future-Proofing

Choose suppliers committed to technological innovation, ensuring your equipment stays current with industry advancements and emerging trends.

The Benefits of Sourcing from Leading CNC Machine Suppliers

Partnering with top-tier cnc machine suppliers yields a multitude of advantages that can redefine your company's market positioning:

1. Enhanced Production Capabilities

State-of-the-art CNC machinery enhances your capacity to handle larger volumes, more complex projects, and diverse materials such as aluminum, steel, copper, and titanium.

2. Superior Product Quality

Precision manufacturing ensures products meet stringent quality standards, satisfying customer demands and reducing rejection rates.

3. Operational Flexibility

Modern CNC systems often feature multi-axis functionality and adaptable tooling, allowing rapid switching between different jobs and customizations.

4. Increased Competitiveness

Efficiency gains and high-quality outputs give your business a competitive edge—attracting more clients and enabling premium pricing.

5. Cost Reductions and ROI

Though initial investment may seem significant, the long-term savings through decreased waste, labor, and cycle time substantially enhance return on investment.

DeepMould.net: A Premier CNC Machine Supplier for Metal Fabricators

As a trusted name in the industry, DeepMould.net specializes in providing comprehensive CNC solutions tailored to metal fabricators' unique needs. Their commitment to quality, innovation, and customer satisfaction has established them as a leader among cnc machine suppliers.

Why Choose DeepMould.net?

- Wide Range of High-Quality CNC Machines: Including high-precision milling centers, turning centers, and multi-axis CNC systems tailored for metalworking.

- Customized Solutions: Equipment designed to meet specific industry or project requirements, supporting various materials and complex designs.

- Technical Expertise: Experienced professionals offering consultation, installation, and ongoing technical support.

- Advanced After-Sales Service: Dedicated maintenance and training programs to ensure optimal machine performance and longevity.

- Competitive Pricing and Flexible Financing: Making high-end CNC technology accessible for businesses of all sizes.

Impact of Advanced CNC Machinery on the Metal Fabrication Industry

The integration of cutting-edge cnc machine suppliers into your manufacturing process facilitates a paradigm shift in how metal fabrication companies operate:

1. Accelerated Innovation and Product Development

Facilitates rapid prototyping and quick iteration of designs, enabling businesses to bring new products to market faster and more efficiently.

2. Increased Customization and Flexibility

Supports bespoke manufacturing, fulfilling the growing consumer demand for personalized products.

3. Enhanced Sustainability

Precision machining reduces waste and energy consumption, aligning with green manufacturing initiatives.

4. Workforce Empowerment

Automated CNC processes reduce dependency on manual skills, allowing your team to focus on higher-value tasks such as design innovation and process optimization.

Future Trends and How to Stay Ahead in the Metal Fabrication Industry

The industry is continually evolving, driven by advances in CNC technology, automation, and digital manufacturing. To maintain your competitive advantage, consider the following emerging trends:

- Integration of IoT and Smart Manufacturing: Connecting CNC machines for real-time data collection, predictive maintenance, and performance monitoring.

- Adoption of AI and Machine Learning: Enhancing machine capabilities for autonomous operation and process optimization.

- Hybrid Manufacturing Systems: Combining traditional machining with additive manufacturing for complex, high-value parts.

- Sustainable Manufacturing Practices: Embracing eco-friendly materials and energy-efficient equipment to meet environmental standards.

Conclusion: Building a Resilient and Growth-Oriented Metal Fabrication Business with the Right CNC Machine Suppliers

In conclusion, the success and sustainability of your metal fabrication enterprise are intrinsically linked to the quality and reliability of your CNC machinery. Partnering with reputable cnc machine suppliers like DeepMould.net can unlock new levels of productivity, quality, and innovation. By investing in the latest CNC technology, fostering strategic collaborations, and staying ahead of industry trends, your business can thrive in a competitive landscape, deliver unmatched products to your clients, and achieve long-term growth.

Embrace the future of manufacturing—your journey to excellence begins with the right machinery and the right partner.